Safety Stock – How Much is Needed?

Posted on November 15, 2016By John Kimball, Senior Consultant, Lanham Associates

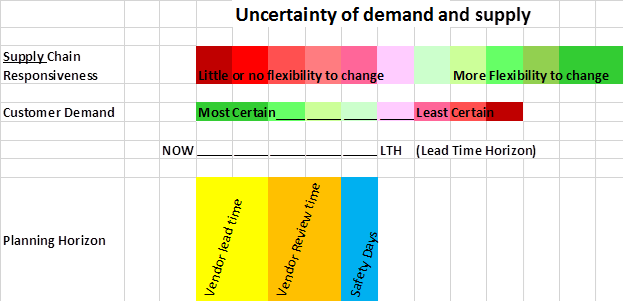

There are only two reasons to have safety stock: uncertainty of demand and uncertainty of supply. And the uncertainty is only important during the time periods when your supply chain has little or no flexibility to change. After you set a safety stock quantity, what can be done to reduce it? To explore this, you’ll need to address these areas:

- Uncertainty of demand.

- Uncertainty of supply.

- The time period with little or no flexibility to change.

Uncertainty of Demand

To predict future demand with more certainty, start with getting sales usage history that accurately represents likely usage in the future. Ideally your demand planning and replenishment system provides a best-fit formula for every item. (See Getting Sales History Right for Forecasting.)

– Consider:

- You may have a situation where a major customer has a select group of items, and after you generate the forecast, further improvement can be achieved through a collaboration process where you get useful amendments to the forecast from the customer.

- In cases where there is a special event or promotion that will drive additional sales, it is helpful to record these quantities separately from the total item forecast so they can be seen and managed.

- When new products are introduced, you can assign a “new item” strategy and increase the frequency of the demand plan review so they can be managed until there is sufficient sales usage history and can then be managed using a best fit formula solution.And finally, getting and maintaining a high level of accuracy in the demand data and improving the flow of information also reduces uncertainty of demand.

Uncertainty of Supply

To maintain certainty of supply, begin by being the best customer you can be. Be a customer that collaborates with your suppliers by sharing your forecast for their items. Suppliers will appreciate this and return the favor with improved delivery performance. Next, you can improve your replenishment planning process in a way that efficiently and quickly guides you to action. Consider how the purchase order is sent to the supplier and whether that can be improved via mail, fax, e-mail or EDI. And, similar to demand data, getting and maintaining a high level of accuracy in the supply data and improving the flow of information also reduces uncertainty of supply.

Time Period with Little or no Flexibility to Change

Question whether your review cycle for each supplier can be revised to a schedule whereby you review and order from each supplier more frequently with the aid of an improved forecasting and replenishment planning solution. For example, with a forecasting and replenishment solution that runs daily and prompts specific actions, you’ll be able to reduce inventories that are held just-in-case someone missed a call to action. Plan for and expect lead times to be reduced by looking for and taking advantage of every lead time reduction opportunity (See 10 Lead Time Reduction Tips to Making Forecast Errors Less Painful.)

How Much Safety Stock?

Once you are actively managing and minimizing uncertainty of demand, uncertainty of supply and the time period with little or no flexibility to change, the need for safety stock will be greatly reduced. Your focus will shift from protecting against many stockout conditions to much fewer conditions. Now each time safety stock is proposed you can determine if reducing uncertainty of demand, uncertainty of supply or the time period, with little or no flexibility, can be reduced instead.

Extra Tip: Start by reviewing those items with the most sales dollars and/or customer line items, your “A” items. These will have the biggest impact on your supply chain performance. To learn more, check out Lanham’s Demand Planning solution. Or register for the 2018 Forecasting & Replenishment Forum, May 8-10 in Scottsdale, AZ.